HZS400 High Performance Granulator

Basic introduction

Model definition

Special Features

Note

HZS series are specially designed for crushing all kinds of plastic, rubber, fabric, leather, cardboards, timber, aluminum foil in the shape of film, sheet, spruce, tubular construction or hollow container. Conveyor belt, ventilator, storage silo and dust collecting system are available for larger output.

|

Type

|

Unit

|

HZS400-800

|

HZS400-800F

|

|

Motor power

|

kW

|

30

|

|

Rotor blades

|

Pcs

|

6

|

|

Fixed blades

|

Pcs

|

4

|

|

Crushing rotary size

|

mm

|

Ø400×800

|

|

Infeed opening

|

mm

|

400×800

|

|

Screen size

|

mm

|

Ø12

|

|

Drive device

|

|

Handle

|

|

Blower power

|

kW

|

—

|

4.0

|

|

Weight

|

kg

|

2000

|

|

|

|

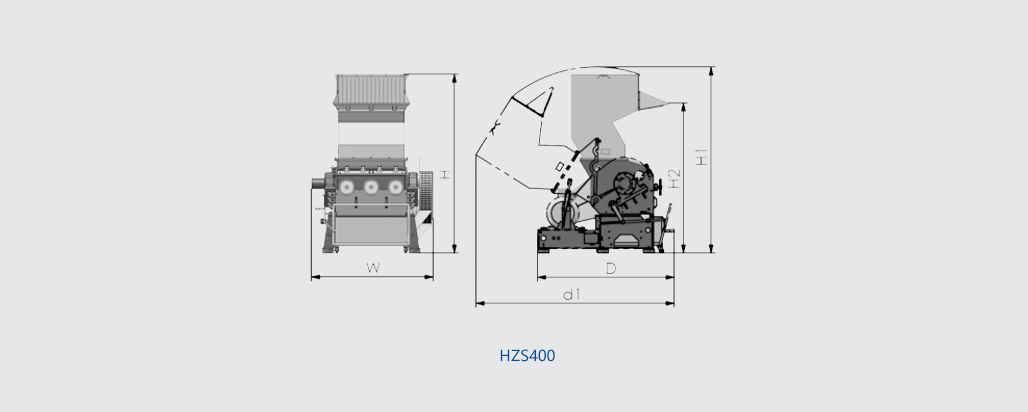

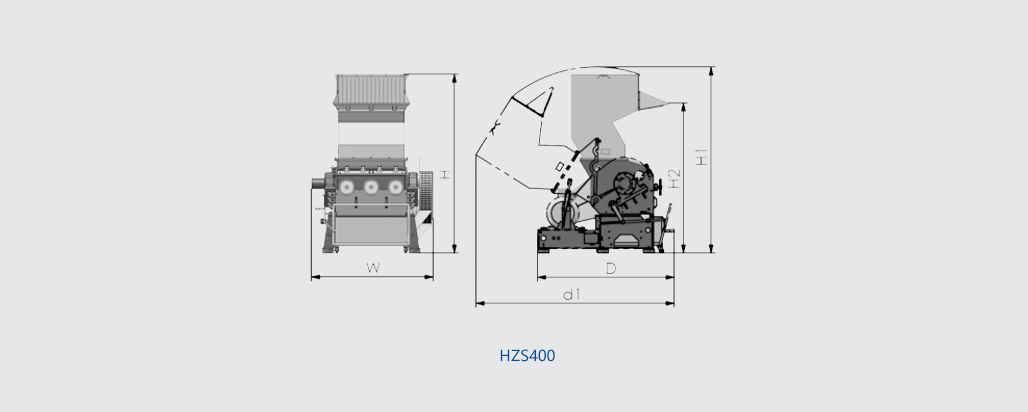

Dimensions

|

|

|

|

H

|

mm

|

2105

|

|

H1

|

mm

|

2225

|

|

H2

|

mm

|

1750

|

|

W

|

mm

|

1500

|

|

D

|

mm

|

1620

|

|

d1

|

mm

|

2435

|

Note

The standard voltage is 3 Phase, 380V, 50 Hz.

The maximum crushing capacity depends on screen hole,

material etc.

Have any special needs, please contact us.

We reserve right to change specifications without prior notice.

HZ - AAA - BBB - CCC

HZS:HUARE high Performance Granulator

AAA:Crushing rotary diameter(mm)

BBB:Crushing chamber width(mm)

CCC:Material out way;

Blank = Manual box;

F= Fan feed;

Rigid steel body to the resistant to impact.

Balanced main shaft to ensure safely smoothly running.

Dual V-cutting geometry to minimize friction between crushing

material and both interior sidewalls ,improve service lift of blades.

Using spherical roller bearings, bearing housing external structure,

good heat dissipation.

3 groups or 5 groups of rotors available depending on different

crushing material.

Optional inertia flywheel to improve cutting strength.