HCM series metering screw doser is suitable for automatic proportioning feeding of materials such as new material, secondary material, color masterbatch or additive in plastic molding production.

This series models use high laugh DC brushless motor. According to the pre-set the proportion and parameters, the microcomputer control system will automatically set the conditions into the speed. Through the coupling drive SUS304 stainless steel precision metering screw, the machine add accurate quantity of material into the injection molding machine or extruder melt cylinder. For example: color masterbatch, mouth water, additives, etc., the error value less than 1%.The product has two modes, suitable for plastic injection molding and extrusion molding. With a variety of models and diameter of the measuring screw to choose, brushless DC motor can be used with different reduction ratio of high efficiency parallel to the gear reducer, can provide 0.1-100kg / h different output for customers to choose.

Another two-color, three-color four-color masterbatch, according to user needs with different occasions to meet the use of different areas.

|

Type

|

|

HCM 3012

|

HCM 3016

|

HCM 3020

|

HCM 3024

|

HCM 5020

|

HCM-D 30XX/30XX

|

HCM-D 30XX/50XX

|

HCM-D 50XX/50XX

|

|

Group Number

|

|

1

|

1

|

1

|

1

|

1

|

2

|

2

|

2

|

|

Gear Ratio

|

|

30

|

30

|

30

|

30

|

50

|

30/30

|

30/50

|

50/50

|

|

Screw Diameter

|

mm

|

12

|

16

|

20

|

24

|

20

|

Combine calculation according to single group selection

|

|

Output Capacity

|

kg/hr

|

0.1-3.8

|

0.3-12.3

|

0.9-40.3

|

1.4-50

|

0.2-24

|

|

Motor Power

|

W

|

30

|

30

|

30

|

30

|

30

|

30×2

|

30×2

|

30×2

|

|

Motor Speed

|

rpm

|

3000

|

3000

|

3000

|

3000

|

3000

|

3000

|

3000

|

3000

|

|

Mixing motor power

|

W

|

90 (Optional)

|

|

Masterbatch hopper

|

L

|

12

|

12

|

12

|

12

|

12

|

12×2

|

12×2

|

12×2

|

|

Net Weight

|

kg

|

15

|

15

|

15

|

15

|

15

|

28

|

28

|

28

|

|

|

|

Dimensions

|

|

|

|

|

|

|

|

|

|

|

H

|

mm

|

530

|

530

|

530

|

530

|

530

|

615

|

615

|

615

|

|

W

|

mm

|

600

|

600

|

600

|

600

|

600

|

1045

|

1045

|

1045

|

|

D

|

mm

|

335

|

335

|

335

|

335

|

335

|

335

|

335

|

335

|

Note

The above output is the ratio of 0.8kg / dm³ diameter of

2-3mm plastic particles in continuous operation of the

measured data, for reference only.

If you need to increase the output requirements or other

related special requirements, please contact us.

Standard voltage: 1 Phase, 220V, 50 Hz;

Have any special needs, please contact us.

Specifications are subject to change without prior notice.

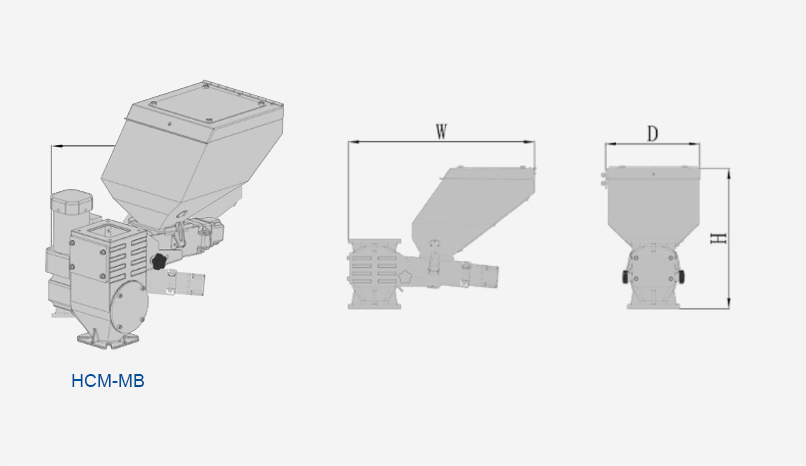

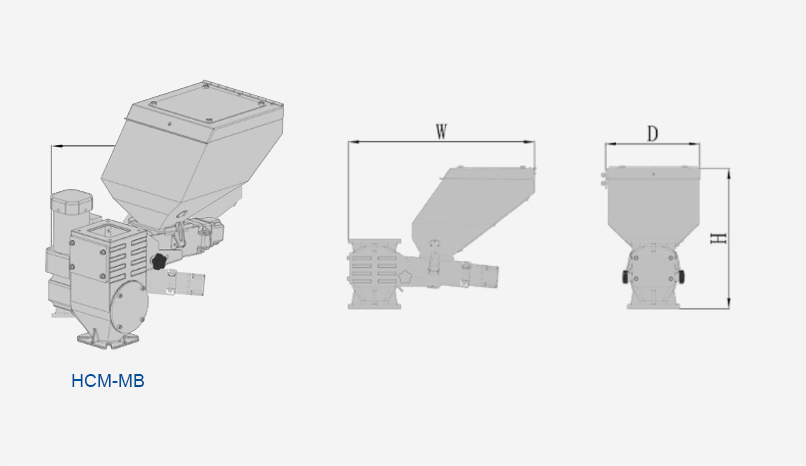

HCM - A - BBB - CCC

HCM:HUARE Metering Screw Dosers

A:Blank = One color, D = two color

BBB:When A=Blank,reduction ratio (2 digits) Screw diameter (2 digits);When A=D,the first set parameters &/& The second set parameters

CCC:MB=Configure the mixing base

Using brushless DC motor, without maintenance, with screw card material, low voltage, overvoltage, over current, disconnection protection, to ensure continuous normal operation of the machine.

The controller has 50 sets of data permanent memory and storage functions to facilitate the management of forming conditions and formulations.

Can meet the injection molding machine or extruder dry contact and voltage, 0-5V, 0-10V, 4-20MA, 2-20MA, frequency, digital, and other signal input, covering almost all plastic molding equipment, plasticized signal.

Modular assembly structure, easy disassembly, can quickly replace the material.

Can be used for extruder main screw synchronous and deceleration operation.

The controller unique compensation optimization concept, to ensure that the measurement of additives is always accurate.

Off-line simulation function, you can quickly adjust the additive to the ideal weight in the equipment debugging process, reduce the loss of debugging process material, greatly reducing the man-made material debugging and material consumption.

Can be used with synthetic filament monofilament, filament spinning equipment using a special mode, to ensure that the spinning equipment of the metering pump free speed control always ensure high stability of the additives to add.

With a special function of the expansion controller optional weighing control module to achieve the proportion of the proportion of digital control, to a greater extent to ensure the accuracy of measurement.

Blanking mechanism to optimize and improve the design of the enhanced installation base to ensure that the amount of large color masterbatch can also be used normally.

Optional material level detection sensor, lack of material alarm

prompt.

Optional mixing base to ensure that the material mix evenly,

generally supporting 100kg dryer or the above models

recommended configuration.