HGB series gravimetric blenders for injection molding, extrusion or hollow molding process used for a variety of raw materials by weight ratio of precision mixing use of the occasion.The series of product controller using the Austrian B & R control system, and the use of adaptive algorithms, in the first boot can be automatically calibrated to ensure accurate accuracy, easy to learn and easy to learn.

The series of products using high-precision AD conversion module to make the batch mixing ratio error (depending on the size ratio of the set ratio) can be controlled at ± 0.1% to 0.5%.According to the need to deal with the type of material and the amount of each hour to choose the appropriate model, the amount of processing per hour from 40 to more than 4000 kg.

|

Type

|

|

HGB-1

|

HGB-2

|

|

-4

|

-3

|

-2

|

-6

|

-5

|

-4

|

-3

|

-2

|

|

Group Number

|

|

4

|

3

|

2

|

6

|

5

|

4

|

3

|

2

|

|

Max. Output

|

Kg/Hr

|

50

|

60

|

130

|

100

|

120

|

160

|

180

|

360

|

|

Knife metering value

|

Set

|

4

|

3

|

2

|

4

|

4

|

4

|

3

|

2

|

|

Trace metering value

|

Set

|

-

|

-

|

-

|

2

|

1

|

0

|

0

|

0

|

|

Max. Throughput

|

Kg

|

1

|

2

|

|

Mixing motor power

|

W

|

90

|

90

|

|

Storage hopper

|

L

|

12

|

40

|

|

Weighing bucket capacity

|

L

|

2

|

8

|

|

Mixing warehouse capacity

|

L

|

8

|

18

|

|

The biggest batch quantity

|

Hr

|

50

|

60

|

130

|

50

|

60

|

80

|

90

|

180

|

|

Dimensions

|

mm

|

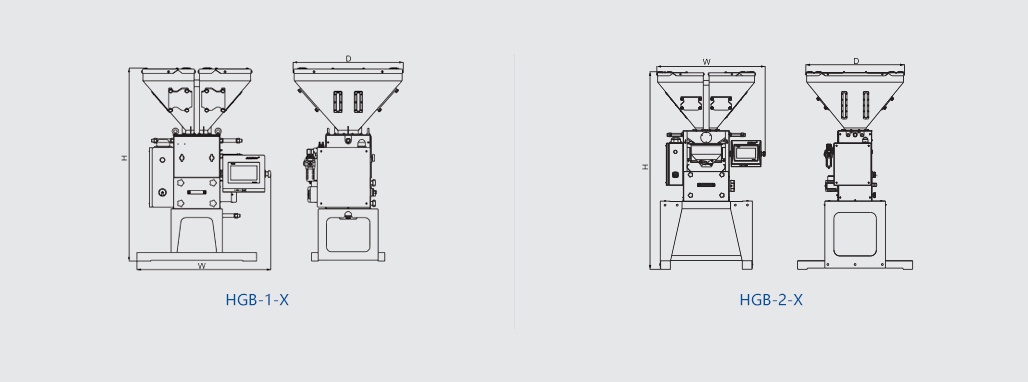

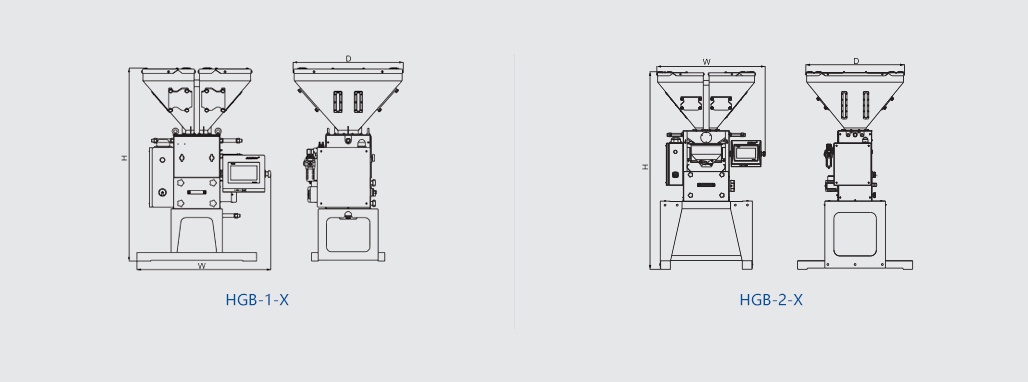

1150×800×650

|

1650×900×1300

|

1650×900×1050

|

1650×900×820

|

|

Type

|

|

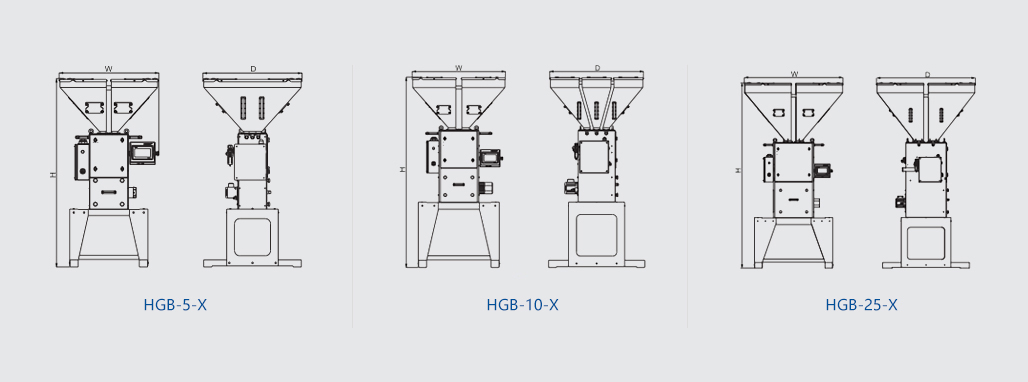

HGB-5

|

HGB-10

|

HGB-25

|

|

-6

|

-5

|

-4

|

-3

|

-2

|

-6

|

-5

|

-4

|

-3

|

-2

|

-6

|

-5

|

-4

|

-3

|

-2

|

|

Group Number

|

|

6

|

5

|

4

|

3

|

2

|

6

|

5

|

4

|

3

|

2

|

6

|

5

|

4

|

3

|

2

|

|

Max. Output

|

Kg/Hr

|

250

|

300

|

400

|

450

|

900

|

670

|

700

|

900

|

1000

|

1800

|

1500

|

1750

|

2000

|

2500

|

4000

|

|

Knife metering value

|

Set

|

4

|

4

|

4

|

3

|

2

|

6

|

5

|

4

|

3

|

2

|

6

|

5

|

4

|

3

|

2

|

|

Trace metering value

|

Set

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

Max. Throughput

|

Kg

|

5

|

10

|

25

|

|

Mixing motor power

|

W

|

200

|

370

|

750

|

|

Storage hopper

|

L

|

48

|

100

|

150

|

|

Weighing bucket capacity

|

L

|

12

|

32

|

65

|

|

Mixing warehouse capacity

|

L

|

25

|

60

|

120

|

|

The biggest batch quantity

|

Hr

|

50

|

60

|

80

|

90

|

180

|

60

|

70

|

90

|

100

|

180

|

60

|

70

|

80

|

100

|

160

|

|

Dimensions

|

mm

|

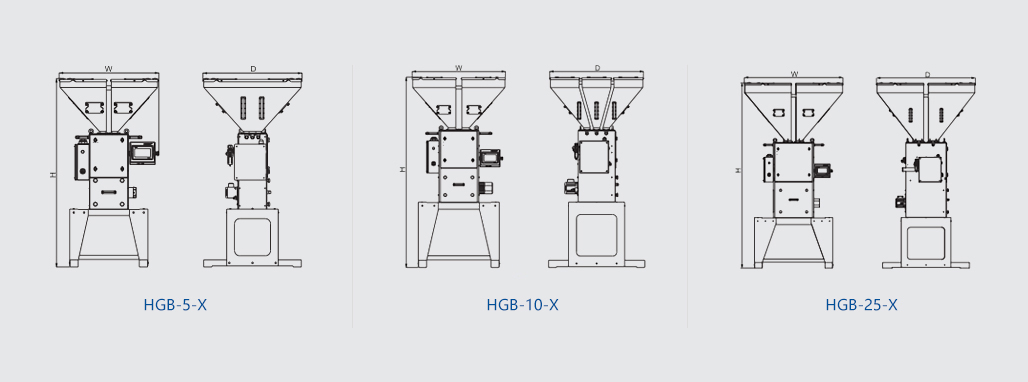

1850×1000×1500

|

1850×1000×1250

|

1850×1000×1000

|

2400×1200×1200

|

3000×1600×1600

|

Note

The mixing ratio error is the difference between the setting percentage

and the actual percentage;

The knife metering valve is suitable for the proportion of 5% and above,

the mixing ratio error can be controlled in ±0.3-0.5%;

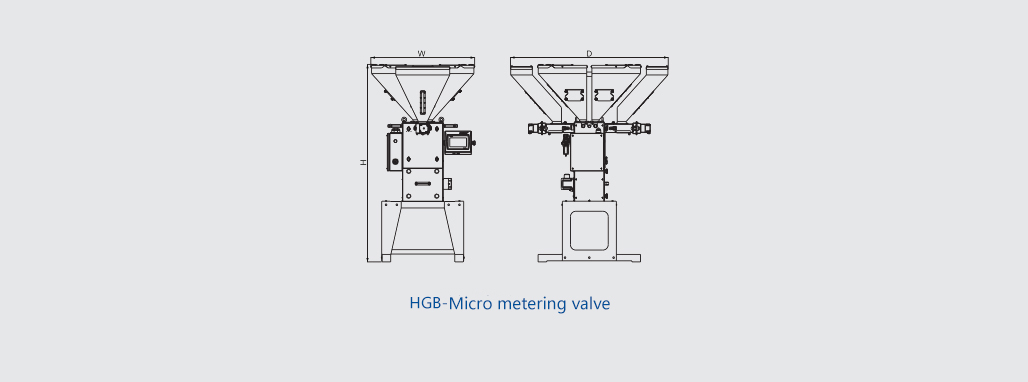

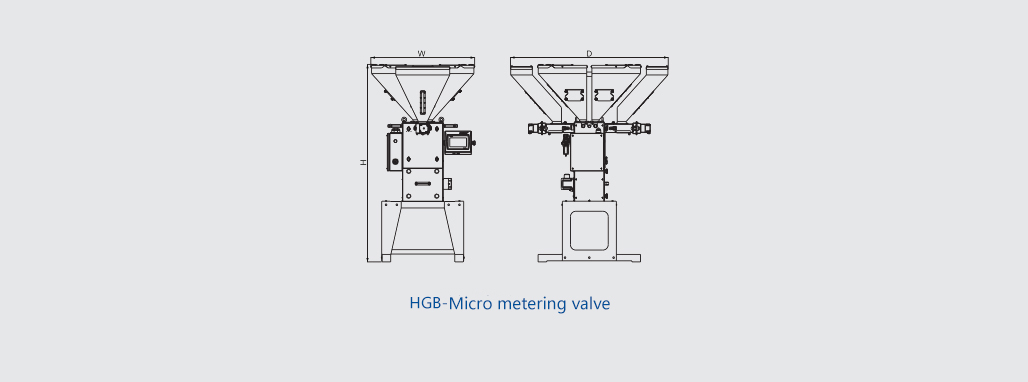

Screw or micro-meter suitable for 5% to 0.5% ratio, mixing ratio error

can be controlled in ±0.2%;

The maximum throughput and the mixing ratio error data are based on

the continuous density of 0.8 kg/L and the diameter of 3-4 mm. The

maximum output will vary according to the number and proportion of the

metering group;

Please ensure the valve pressure 6kgf/cm² ;

Standard voltage: HGB-5 and below models 1 Phase, 220V, 50 Hz, HGB-

10 and above models 3 Phase, 380V, 50Hz;

Have any special needs, please contact us;

Specifications are subject to change without prior notice.

HGB - AAA - BBB

HGB:HUARE Gravimetric Blenders

AAA:Maximum batch throughput (kg)

BBB:Hopper groups

All materials are weighed and uniformly mixed to strictly control the accuracy

Advanced batching technology can precisely control and measure the ratio of each treated raw material

After each weighing automatically repeat calibration function will automatically correct, adjust, to ensure the best batching accuracy

Up to six kinds of raw materials can be processed at the same time

Modular detachable structural design, easy to clean

With recipe storage function, can store up to 20 sets of recipes

With alarm history function

Standard configuration for machine-mounted (with standard base, manual pallet)

Optional USB data export function, you can record the ratio of data stored for the production of quality management

European regulations safe circuit type, model after filling \"CE\"

You need optional mounting frame, pneumatic discharge valve,

storage bin and suction box when the machine is used for

ground installation.